Aws Cwi Can Be Fun For Everyone

Aws Cwi Can Be Fun For Everyone

Blog Article

All about Aws Cwi

Table of ContentsAws Cwi for BeginnersSome Known Incorrect Statements About Aws Cwi Little Known Facts About Aws Cwi.The Facts About Aws Cwi UncoveredGetting The Aws Cwi To WorkAws Cwi - Questions

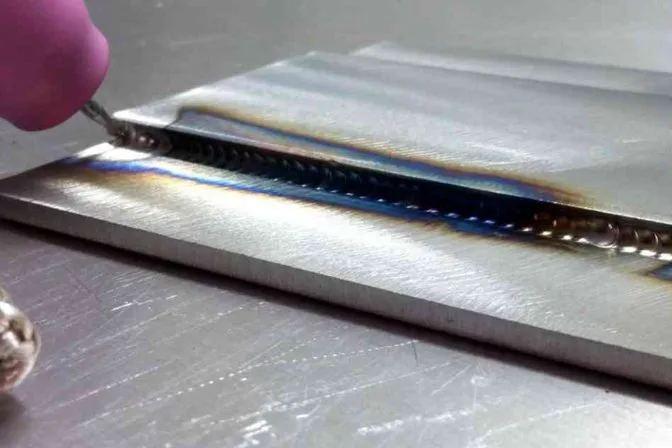

Plans, directs, collaborates, monitors, and carries out tasks connected to guaranteeing that evaluations of structural steel manufacture are finished to the needs of relevant specs and codes. Functions with company-wide QC team and fabrication teams to establish quality requirements and treatments, and identify top quality renovation possibilities.Different welding criteria, including as weld dimension, support, fillet dimension, weld insurance coverage, and placement, are examined to ensure the weld appertains and of excellent quality. To ensure the welded link satisfies the performance and weld top quality approval criteria, every aspect of the weld is visually examined. We do third-party witness and inspection of welding methods and welder examinations, which help in reaching high quality at its ideal rate with market secure criteria.

Driver requirements for welding automation. Materials that we process our testing services on: Processes for welding consist of.

Applications include sheet steel, steel constructions, stress vessels, storage space tanks, and piping.

The Buzz on Aws Cwi

While we realize that not every weld has to have the quality of a sanitary weld, the significance of compliance with relevant codes and needs have to be taken seriously. The majority of acceptance standards for welding are based on style requirements, the service problems, and the extent and frequency of evaluations. Typically, the authorization of welding procedures and welder is done based on the supplier's item scope and/or according to task applications.

If a supplier sells items worldwide, including in Europe, extra requirements or complementary needs to the ASME Code, as an example, must be considered and might be required. Our mechanical designers, licensed welding designers (International/European Welding Design [IWE, EWE], licensed welding assessors (CWI AWS D1.1), and qualified welding supervisors are educated to execute procedure and performance approvals, consisting of Welding Treatment Credentials Document (WPQR) and Welding Treatment Specs (WPS), as well as Performance Certifications (PQ) for welder and welding operator.

Essentially, welding evaluation shows minimum appropriate levels of a bonded product according to particular criteria and approval criteria. Welding Assessors examine the connections and bonds in between steels. Assessors use visual tools and electric instruments to examine and ensure the quality and safety and security of connections. Certified welding assessors play an intrinsic function in the welding industry.

This job path comes with a whole lot of obligations. It is likewise incredibly gratifying for those who are enthusiastic concerning the occupation. Individuals from various histories get right into welding evaluation. Welders, producers, foremen, or NDT drivers, and any individual operating within this industry field can fit right into the welding assessor duty criteria.

9 Easy Facts About Aws Cwi Shown

Welding evaluation as a certification is a really great starting factor in the sector's inspection side. Numerous welding assessors often relocate right into NDT locations, plant inspection, cathodic protection, paint and coating assessment, or underwater inspection. Within the welding inspector career path, there are various routes one can pick to specialise in and perform multiple sorts of jobs.

In terms of location, there is a need for certification holders and qualified assessors in practically every country. CSWIP certifications can lead to several different roles., and numerous various other areas are covered in the CSWIP plan.

You would certainly additionally have the alternative of freelancing or working as a professional. This alternative not only provides you with a lot of adaptability and autonomy for picking the type of job, however it likewise develops the possibility of traveling to different areas for job. Generally, qualified welding inspectors enter into the function through need due to the fact that it is either the agreement need or the customer demand as it provides self-confidence in their items and services

9 Easy Facts About Aws Cwi Described

As you go into the extra senior functions, it gets even more certain concerning what the inspectors need to do and exactly how much experience they need to supply.

A Welding Inspector should guarantee all the welding and connected actions are brought out per the requirements and any kind of applicable procedures. In addition to working in the field and finishing their examination of welding projects, examiners hang out compiling the reports in a workplace setting (https://sandbox.zenodo.org/records/109873). Most of assessors work with a full-time basis, mainly throughout business workdays

Aws Cwi for Beginners

In regards to location, there is a requirement for certificate owners and qualified examiners in nearly every nation. CSWIP credentials can result in several different functions. We have credentials that cover welding evaluation, welding evaluation, welding direction, NDT, plant Inspection, cathodic security, undersea evaluation, and many various other locations are covered in the CSWIP scheme.

Oil and gas, manufacturing, building, transport, and aeronautics are several of the examples of the numerous markets that use chances for qualified welding assessors. Welding assessors who aspire and wish to specialise in numerous methods or products can obtain various certifications which permits them to enhance their employability in multifunctioning roles, which causes better-earning ability.

You would certainly also have the alternative of freelancing or working as a specialist. This choice not only offers you with a large amount of adaptability and freedom for choosing the kind of project, yet it likewise develops the opportunity of taking a trip to different areas for job. Usually, certified welding assessors come right into the duty via need due to the fact that it is either the contract demand or the client demand as it reassures in their products and solutions.

As you go right into the much more senior duties, it obtains more details regarding what the inspectors need to do and just how much experience they need to provide.

The Best Guide To Aws Cwi

Companies with certified welding inspectors have the confidence that their staff recognizes the sorts of products and issues they are checking out. They are confident that the group can assess versus criteria appropriately, and it gives them confidence in the item that is being released at the end of manufacturing.

A Welding Assessor should make certain all the welding and associated activities are performed per the spec and any type of applicable treatments. Along with operating in the field and completing their assessment of welding tasks, inspectors hang around assembling the reports in an office setup (Welding Inspection Company). Most home of examiners work with a permanent basis, largely during company workdays

Report this page